-

-

Mobile: +971 58 677 7772

Email: sales@ykmgroup.com

Mobile: +971 58 677 7772

Email: sales@ykmgroup.com

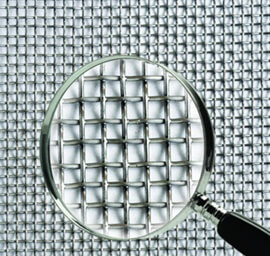

Wire Acceptance Inspection :

Based on the quality management policy of “Elaborately weaving, Create excellence together, Management in earnest, Sincere service”, YKM has been strictly implementing the quality management system. Our laboratory has been rated as the engineering laboratory at the provincial level, reinforced the ability on testing and application environment simulation, to meet the special quality requirement from customers. During the R&D stage, we have fully considered the consistency of product manufacturing so as to meet customers’ quality expectation on new products.